Every day millions of precision parts are manufactured using CNC Machine technology. Computer Numerical Controlled (CNC) Machining Technology is one of the most accurate, cost-effective & commonly used subtractive manufacturing technologies to produce parts in a wide range of end usable materials. Here's are the types of CNC machines.

Today the world is developing rapidly, and we keep finding something new daily regarding manufacturing technologies. From subtractive manufacturing where a solid block is cut and shaped to form the desired part to additive manufacturing where the part is produced by joining layer by layer using a 3D CAD file, the manufacturing technology has grown continuously. However, it wouldn’t be wrong to say that though there have been advancements in manufacturing technology left and right, none have thoroughly beaten the CNC technology. Every day millions of precision parts are manufactured using CNC Machine technology. The operations using the lathe, milling, and drilling machines can be easily carried out manually. Still, they would not be able to match the accuracy and precision of the CNC machines.

What Is CNC Machining?

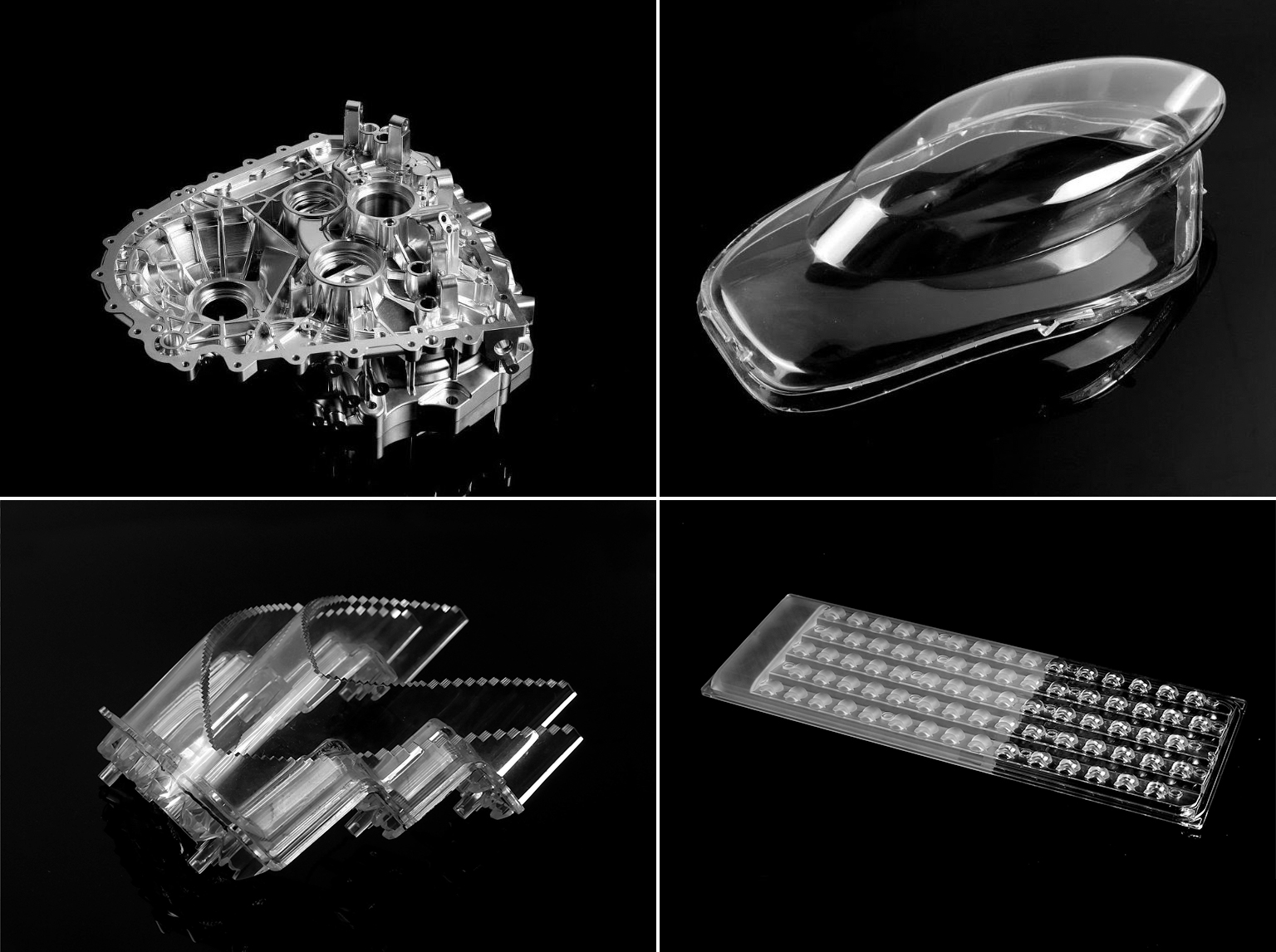

Computer Numerical Controlled (CNC) Machining Technology is one of the most accurate, cost-effective & commonly used subtractive manufacturing technologies to produce parts in a wide range of end-usable materials. It has been popularly used in material removal, shaping, and fabrication. Here the material is removed from a block with various precision cutting tools to make a product. The first step involves creating a CAD file (Computer-Aided Design) which is then converted into a G-code and fed into the machine. Once the programming is done, the next step involves choosing the material in plastic or metal and is machined by high-speed cutters controlled by a code. Advanced software is used to control the equipment according to the design specifications. Then, a team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet specifications.

CNC machining is a digital manufacturing technology that makes highly accurate, durable, and reliable parts from a CAM file with high tolerance as low as 2 microns in a variety of materials, including ferrous, non-ferrous, precious metals and thermoplastics. Some solid metals like aluminium, steel alloys, brass, titanium, etc., and plastics such as ABS, Delrin, Nylon, and more can be CNC machined. In addition to it, foam, composites, wood, glass etc., can also be shaped using CNC machining technology.

CNC Applications:

CNC Machining has been used in various industries, right from making wooden furniture, to super-accurate components for Aerospace, or critical components for Automotive. This manufacturing technology is used to manufacture parts and prototypes. It is optimal for one-off custom prototypes as well as series production for 1000s of parts. CNC machines are the key machines for the mould making or die casting industry. It is the most widely used and important manufacturing technology.

Different Types of CNC Machines

- CNC Lathes and Turning Machines - Machines are characterized by the rotating or turning ability during the operation. The Lathes in a CNC lathe machine are used in turning centres whereby the material is rotated rapidly on a spindle and a cutting tool is used to shape it in the desired form. They use rotary cutters to shave, cut and slice the selections of a workpiece. The turning machine can be programmed to vary in depth, angle, and direction to give you greater and accurate precision. It is used in automotive, aerospace, firearms and many other such industries. Additionally, these machines are also common for glass working, metalworking, woodturning, and more.

- CNC Milling Machine - CNC mill is a large machine compared to other tools and has a wide array of functions like face milling, shoulder miller, tapping, drilling, and turning. The computer-based G-code will guide the tools to drill or cut the material. CNC Milling machines are available in three-to-six axis configurations. Milling machines can be classified as HMC (horizontal machining centres) and VMC (vertical machining centres). The HMC has an x-y table with a cutter mounted on a horizontal arbour across the table, while VMC has its spindle axis, the z-axis, vertically oriented. CNC Milling machines are used for an array of industries including medical, electronic appliances, automotive, energy, agriculture, military, aeronautic technology, and more. CNC Turning and CNC milling are penned under the same term - CNC machining but they are different. A CNC turning machine is commonly used for cylindrical parts while the milling machine is used to create complex parts by carving away the excess material.

- CNC Plasma Machine - The process of CNC plasma cutting involves the cutting of material using a plasma tool to cut the materials. These machines, however, differ from their milling counterparts, as their high-powered torch can cut through rough materials like metal. The gas is blown at a very high speed from a nozzle. While this is happening, an electric arc forms through this gas. This electric arc converts some of the gas into plasma. Plasma temperatures range from 10,000-50,000 degrees. It is hot enough to melt the material being cut and it also blows away the molten metal from the site of the cut. The CNC Plasma Machine is specifically used for steel, stainless steel, aluminium, brass, copper, and many other conductive metals. It is usually used in the manufacturing, automotive repair and restoration industry, industrial construction, salvage, and scrapping industries.

As you might have read, there are various types of CNC machines all of which serve different functions. It is, however, essential to have a clear understanding of how these machines work and what they are actually capable of. Remember, each CNC machine has its own unique features and uses and it is always advisable to opt for expert guidance.

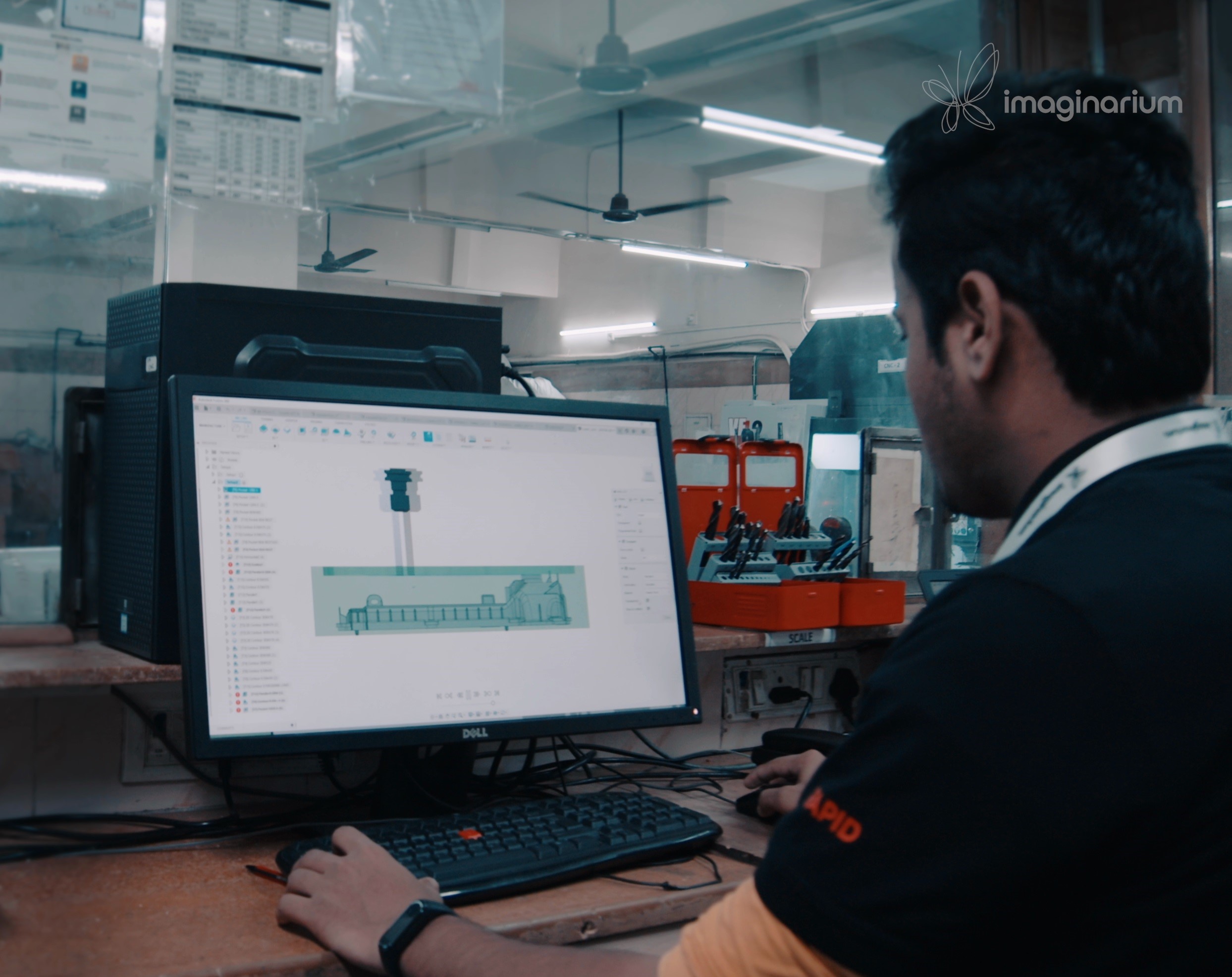

At Imaginarium, our manufacturing & technical experts are at your service round the clock globally to assist you. We offer our clients CNC Turning, CNC Lathes, 3 Axis and 5 Axis CNC Milling services. We provide you with high-quality precision quality parts with a quick turnaround and unbeatable quality.

Connect with us today on 91 22 6738 0100 or hello@imaginarium.io

Here’s a quick glimpse of our fully equipped CNC shop floor.