Rapid & Production Tooling

WHAT IS RAPID TOOLING?

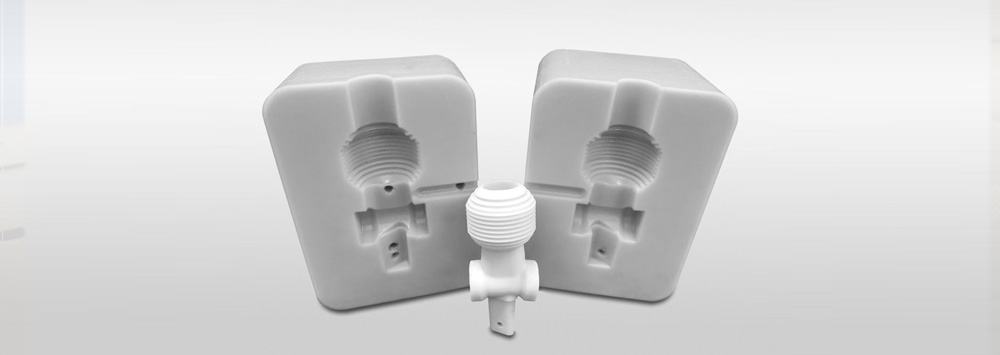

Rapid Tooling is when Rapid Prototyping techniques and conventional tooling practices are used together to produce a mold quickly. This process is also used to prepare parts of a model from CAD data in less time and at a lower cost compared to traditional manufacturing methods. Rapid Tooling is used as a channel to produce injection molded parts.

APPLICATIONS:

Injection moulding is used for rapid prototyping and for low-high volume manufacturing. It is used for producing parts in the thousands. Well known examples of injection moulding are lego bricks, bottle caps, and medical syringes.

HOW DOES IT WORK?

The injection moulding process has three major components; an injection moulding machine, raw plastic, and the machined mould. The raw plastic is melted in the injection moulding machine and then injected into the mould where it cools and solidifies into the final part. Once the part has cooled, it is removed and finished.

ADVANTAGES OF RAPID TOOLING

HIGH VOLUME MANUFACTURING

More output as compared to other manufacturing processes.

WIDE RANGE OF MATERIALS

Most thermoplastics and some thermosets and silicone can be injection moulded.

REDUCE PROCESSES

Complex assembly processes can be consolidated into one process.

REPEATABILITY

The mould can produce a large number of products without wearing out.

MATERIALS USED IN RAPID TOOLING

ABS

ABS is a thermoplastic with high impact resistance, low density, and low cost. It is reinforced with glass fibres. Available in ABS 30% GF and ABS 40% GF.

NYLON GF'S

Nylon is a thermoplastic with great mechanical properties and high chemical and abrasion resistance. It is reinforced with glass fibres. Available in Nylon 30% GF and 40% GF.

PP

Polypropylene is the most common material used in injection moulding and has high chemical resistance. Also available in food grade.

PA6

PA6 is a performance plastic with a high degree of toughness and good surface finish.

PA12

PA12 is a performance plastic with low moisture absorption, high dimensional strength, and flexibility.

HDPE

High density polyethylene has a high strength-to-density ratio, impact resistant, and long lasting.

LDPE

Low density polyethylene is flexible, had good impact resistance, lightweight with high strength.

POM

Polyoxymethylene has high temperature resistance, excellent chemical resistance, and good dimensional stability.

PRODUCTION AND

EXPORT TOOLING

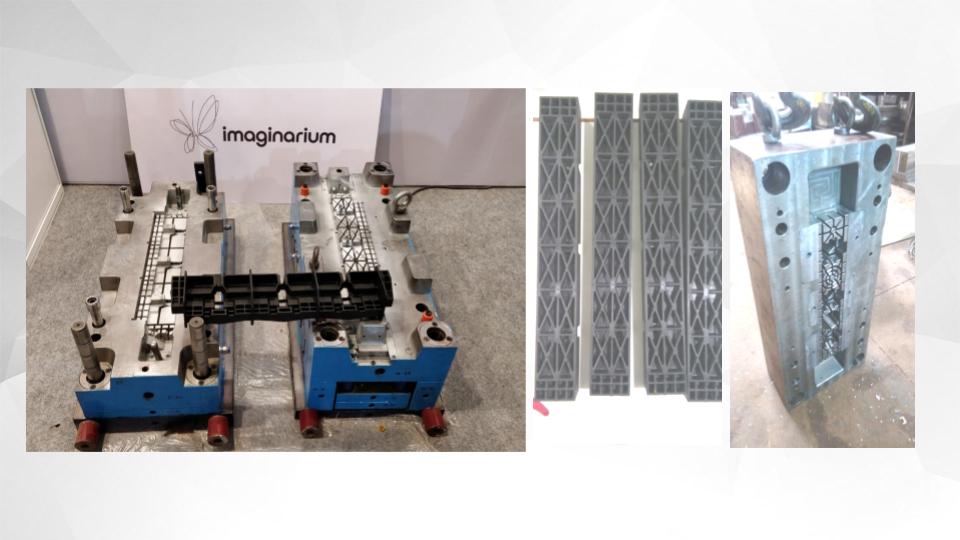

- We provide high production tooling for in house molding or for export.

- Single Cavity, multicavity, family molds,2 shot, Hot Runner Valve gate,

- Tooling materials for production molds are typically P20, H13, S7, NAK80.

- Customers can select materials types when quoting

- All export molds are sampled and run for several hours to ensure good operation prior to shipping..

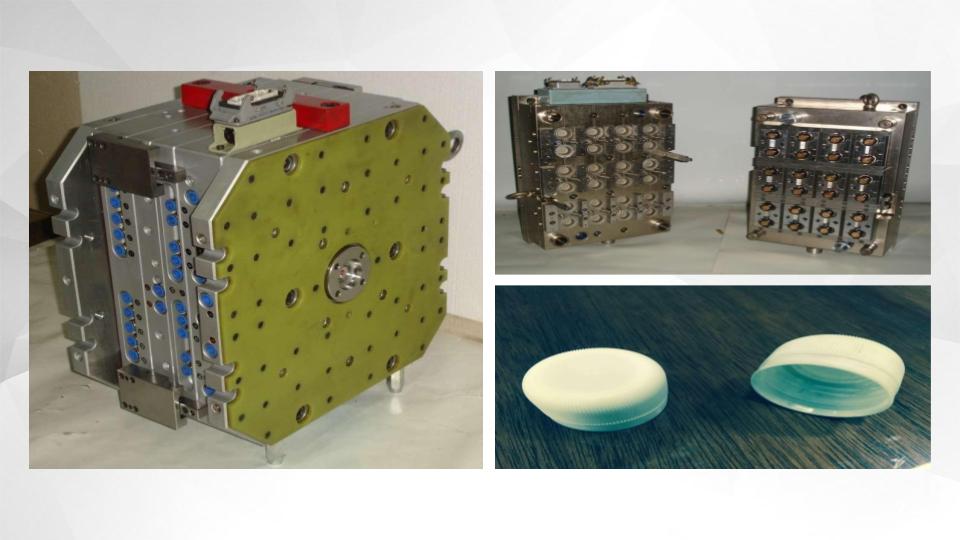

PRODUCTION MOULDS

TOOLING FACILITY

INJECTION MOULDED PARTS

Access our entire suite of manufacturing services with Rapid Online Factory In Just a few Clicks.

Log on to rapid.imaginarium.io to turn your concepts into reality today.