ADVANCED

MANUFACTURING,

MADE EASY

ADVANCED

MANUFACTURING,

MADE EASY

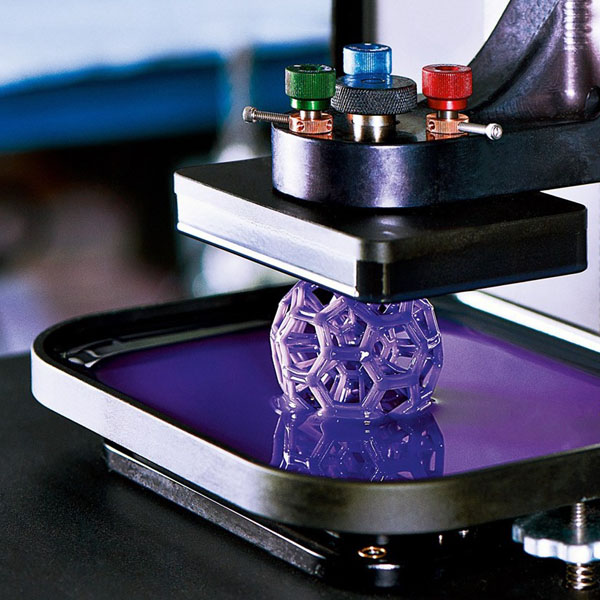

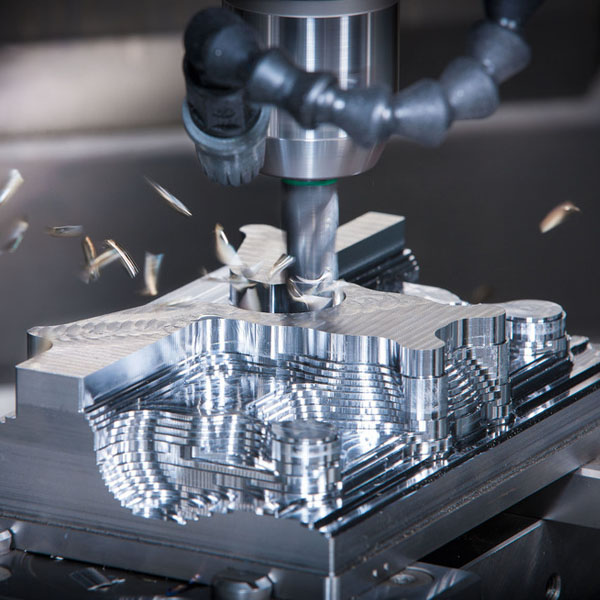

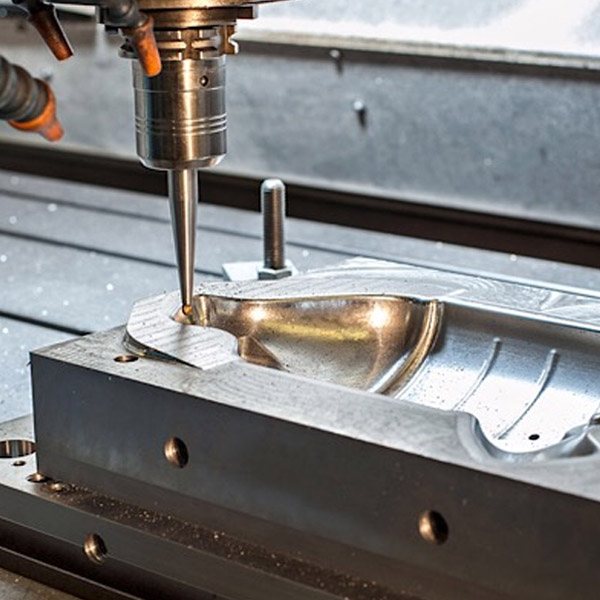

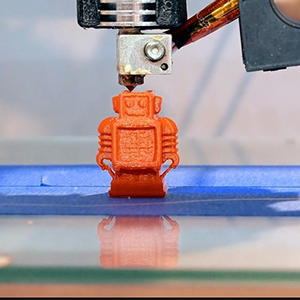

From Prototyping To Production, we are your partners in bringing ideas to life with our cutting edge Advanced Manufacturing services

INTRODUCING

THE RAPID ONLINE FACTORY.

INTRODUCING THE RAPID ONLINE FACTORY.

MANUFACTURING MEETS THE CLOUD

A one-stop shop for all your manufacturing needs that takes your digital designs to finished products in just a few days. We offer a full spectrum of prototyping and small batch manufacturing services accessible right from your browser.

Access our entire suite of manufacturing services in just a few clicks. Log on to rapid.imaginarium.io to turn your concepts into reality today.

COMPLETE YOUR ORDER IN JUST 4 EASY STEPS

BENEFITS OF RAPID ONLINE FACTORY

Instant Quote

24 Hours Access

Widest Range of Processes & Materials

Manufacturability Checking

OUR SERVICES

OUR SERVICES

Empowering manufacturing with expertise across processes. Access our entire suite of manufacturing services & turn your concepts into reality today.

TESTIMONIALS

QUICK FACTS

TESTIMONIALS

THE PRESS

THE PRESS

ACCESS ADVANCED MANUFACTURING

ACCESS ADVANCED MANUFACTURING

Contact Us Now

THE IMAGINARIUM GROUP

THE IMAGINARIUM GROUP

Imaginarium is a leader in 3D printing and Advanced Manufacturing technology. Having pioneered game-changing applications for various industries since over a decade, Imaginarium has helped disrupt manufacturing by enabling enterprises and individuals to design better, prototype faster and create high quality products. We are grooming the next breed of makers and innovators for another manufacturing revolution.

PRECIOUS

Crafts meets

technology

RAPID

From concept to Product

LIFE

Patient specific solutions

SOLUTIONS

Customized expertise

ACADEMY

Accelerating

adoption

VENTURES

Investment

in ideas